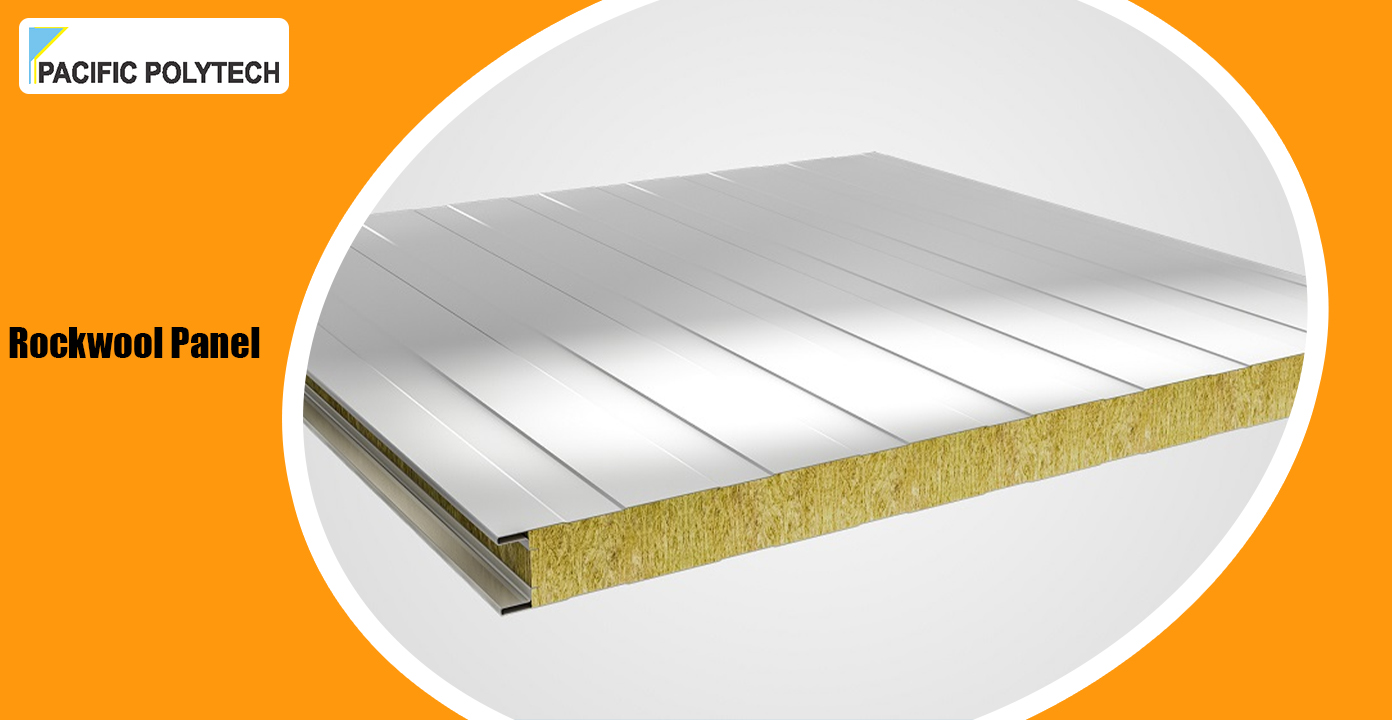

In high-demand industrial environments where insulation, fire resistance, and durability are non-negotiable, the Rockwool Panel stands out as a superior material engineered to deliver unmatched thermal and acoustic protection. Designed from high-density mineral wool sandwiched between two metal facings, this structure offers stability, safety, and energy efficiency in one robust solution.

Pacific Polytech, a reputed Wholesale Supplier and Wholesaler, specializes in manufacturing and distributing high-performance Rockwool Panels that meet stringent global standards for modern construction and process industries.

The Rockwool Panel is composed of non-combustible mineral wool fibers derived from basalt rock. These fibers are compressed between pre-coated galvanized steel or aluminum sheets, forming a rigid sandwich structure that provides exceptional dimensional stability.

Each layer serves a critical purpose:

This engineered combination allows the Rockwool Insulated Panel to perform efficiently in demanding temperature conditions and under continuous operational stress.

The Thermal Insulation Panel properties of Rockwool stem from its extremely low thermal conductivity (typically around 0.035 W/mK). This ensures minimal heat transfer through building envelopes such as walls, ceilings, and roofs.

Industries that require temperature-controlled environments like cold storage, pharmaceuticals, and food processing benefit greatly from this material.

By reducing heat gain or loss, Rockwool Panels help facilities maintain operational stability while cutting energy costs. Pacific Polytech ensures uniform density and precise lamination, optimizing insulation performance for both external and internal applications.

Fire safety is one of the defining features of Rockwool Panels. The mineral wool core is non-combustible and classified under Euroclass A1 for fire resistance. It can withstand temperatures up to 1000°C without releasing toxic fumes or smoke.

For industries such as petrochemical processing, automotive manufacturing, and power plants, Fire Resistant Panels made by Pacific Polytech act as a critical safety layer. The outer metal facings enhance fire integrity, while the Rockwool core prevents flame spread, providing an excellent barrier for compartmentalization and fire-rated walls.

Sound management is crucial in industrial and commercial facilities. Rockwool Panels offer an excellent Acoustic Insulation solution by absorbing and dissipating sound energy through the open-fiber matrix of the mineral wool.

Noise levels in factories, workshops, and machinery areas can be significantly reduced, improving working conditions and regulatory compliance.

Laboratories, cleanrooms, and commercial centers also use Rockwool Sandwich Panels to maintain quiet, controlled environments. The panels’ high Sound Transmission Class (STC) ratings make them ideal for modern infrastructure where both insulation and noise control are essential.

Rockwool Panels maintain their shape and structural integrity even under load, vibration, and temperature fluctuations. The dual metal facings provide rigidity and protection against mechanical impact, while the Rockwool core prevents compression and deformation.

The panels exhibit excellent load-bearing capacity, making them suitable for vertical cladding, partition walls, and suspended ceilings. Pacific Polytech uses precision roll-forming and high-pressure lamination to ensure consistent bonding and durability across every unit produced.

While Rockwool is known for its porosity, proper sealing and coating make it highly resistant to moisture absorption. The protective coating on the metal sheets shields against corrosion, UV exposure, and chemical attack, ensuring long-term performance even in humid or saline conditions.

This property makes Rockwool Panels ideal for industrial roofing and wall cladding systems in coastal, humid, or chemical-prone environments. Additionally, the panels’ eco-friendly composition makes them sustainable and recyclable, supporting green construction practices.

| Parameter | Specification |

|---|---|

| Panel Thickness | 30 mm to 200 mm |

| Density of Rockwool Core | 100 to 150 kg/m³ |

| Thermal Conductivity | 0.035 to 0.040 W/mK |

| Fire Rating | Up to 120 minutes (depending on thickness) |

| Sound Absorption Coefficient | 0.90 NRC |

| Facing Material | Pre-Painted Galvanized Steel / Aluminum Sheet |

| Sheet Thickness | 0.4 mm to 0.8 mm |

| Standard Width | 1000 mm |

| Length | Customizable up to 6 meters |

| Surface Coating | Polyester / PVDF |

| Core Adhesion | Continuous lamination under controlled temperature |

| Water Absorption | < 0.2% by volume |

| Compressive Strength | 80 to 150 kPa |

| Tensile Strength | > 7.5 kPa perpendicular to face |

| pH Neutrality | 7 to 8 (non-reactive) |

| Temperature Range | -50°C to +800°C |

Each technical specification is designed to ensure high efficiency, stability, and longevity in industrial and architectural applications.

The versatile nature of Rockwool Insulated Panels makes them essential for a variety of sectors:

Pacific Polytech, as a Rockwool Panel Wholesaler, caters to both small-scale and large-scale projects with customization flexibility and consistent supply.

The Rockwool Panels supplied by Pacific Polytech comply with international environmental standards. The material is non-toxic, asbestos-free, and recyclable. The energy efficiency achieved through insulation reduces overall carbon emissions of buildings, making these panels a sustainable choice for modern construction.

In addition, Rockwool’s inert chemical nature ensures that it does not degrade, rot, or release harmful gases over time, providing long-term safety and sustainability.

As a trusted Wholesale Supplier, Pacific Polytech ensures that each Rockwool Panel undergoes rigorous quality testing for density, adhesion, compressive strength, and surface coating. The company employs automated manufacturing lines, precision bonding systems, and advanced curing technologies to guarantee consistency and reliability.

Every batch is inspected for dimensional accuracy, core bonding uniformity, and corrosion resistance, ensuring products meet the performance expectations of global clients.

Q1. What is the main advantage of Rockwool Panels over other insulation materials?

They offer superior fire resistance, thermal insulation, and acoustic absorption compared to EPS or PU panels.

Q2. Can Rockwool Panels be used in humid environments?

Yes, when properly coated and sealed, they offer excellent moisture resistance and long-term durability.

Q3. What is the standard density of Rockwool Panels?

Typical density ranges from 100 to 150 kg/m³, depending on application requirements.

Q4. Are Rockwool Panels environmentally friendly?

Yes, they are made from natural stone and are fully recyclable and non-toxic.

Q5. Where can I source premium-quality Rockwool Panels?

You can source them directly from Pacific Polytech, a leading Wholesale Supplier and Wholesaler of Rockwool Panels for industrial and commercial applications.